Interface Rollforming Controllers

EBMS contains tools to push metal orders directly to the Beck and AMS roll formers. The EBMS order entry system formats order files that meet the specifications defined by the Beck SmartComm Import and Export File Specification.

Batch data, such as the quantity and lot of the materials consumed, is communicated back into the EBMS system to compile an accurate inventory and cost details for each order.

Configuration

Complete the following steps to integrate an approved roll form controller to the EBMS metal order entry system:

-

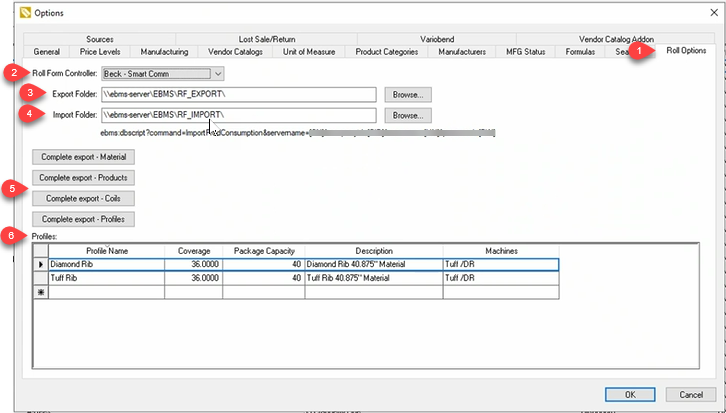

Select Inventory > Options > Roll Options tab from the main EBMS menu to open the following dialog:

-

Select one of the approved Roll Form Controllers.

-

Set the Export Folder. This user defined folder is used to store the export processes CSV order files. These files must be accessible from the role form controller software.

-

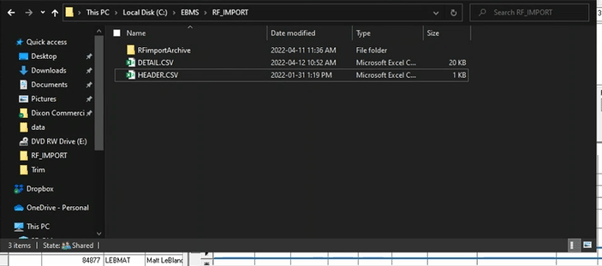

Set the Import Folder. The import process will read the Details .CSV file created by the role form controller.

An archive subfolder is created by EBMS to store files to process and archive. -

Use the Complete export buttons to push needed information to the controllers.

- Configure the profile options such as Coverage, Package Capacity, and Machines. Enter a Profile Name and Description to identify each profile.

-

Save options and export a sample order to the roll form machine.

Export to Controller

Orders are exported to the controller by sales order. Complete the following steps to export a completed order to the roll form controller:

-

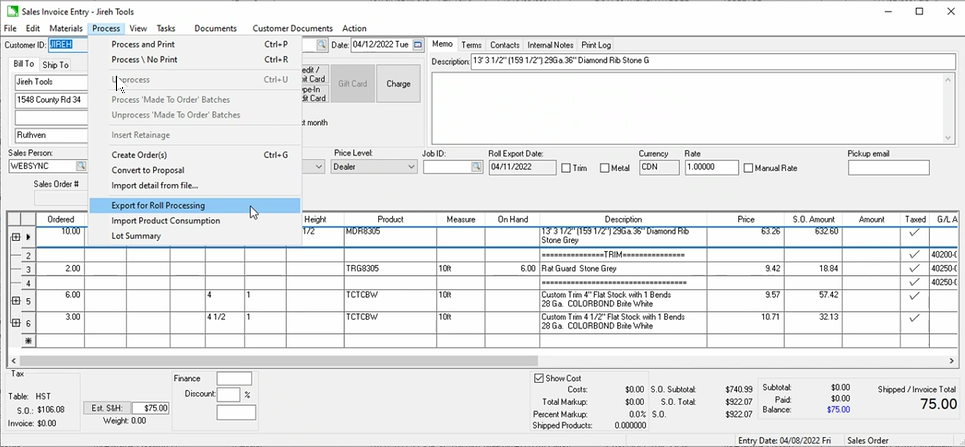

From Sales > Invoices & SO's, double-click on a sales order that includes metal panels to open the order.

-

Select Process > Export for Roll Processing from the sales order menu as shown below:

-

The CSV file created and placed in the Export Folder identified within the Inventory > Options > Roll Form Options tab. The controller will read, import the file data, and then delete the file from the folder.

-

Complete the Import from Controller to import the results of the batch after the metal panels have been created.

Import from Controller

Select Process > Export for Roll Processing from the sales order menu to import the information from the controller into the EBMS order system. The quantity of raw materials (coil) used as well as the specific coil or lot used to fulfill the order.

Select Process > Lot Summary to view a summary of the coil stock.