Stock Level Settings

Managing safe stock inventory levels by calculating the magical balance of minimal inventory while meeting variable customer demands can be a significant business challenge. Optimizing stock levels can be especially challenging if products vary dramatically based on seasonality or if the life cycles of the products vary substantially.

Set Stock Level Settings Manually

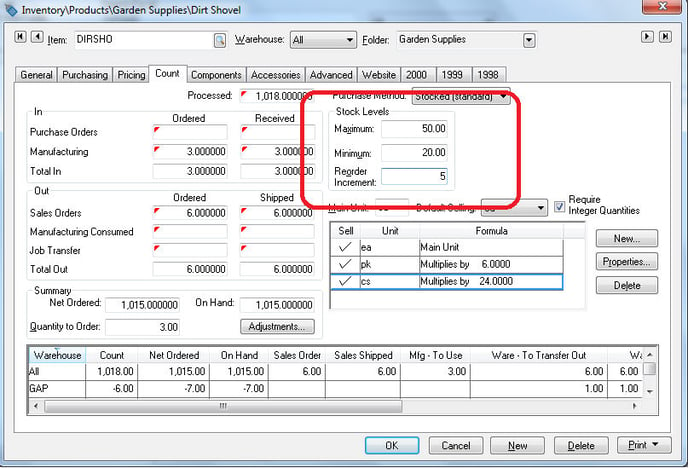

Settings for Stock Levels are found within the product record Count tab as shown below:

These settings can be set manually. Review the Creating Purchasing Parameters section for more details on these important settings.

Standard Stock Level Settings Utility

The Calculate Stock Level Settings utility is launched to calculate the Minimum and Maximum stock level settings for all or a group of products. This utility can be launched as often as necessary. Complete the following steps to launch the Calculate Stock Level Settings utility:

-

Select Inventory > Utilities > Calculate Stock Level Settings from the main EBMS menu to launch the wizard.

-

Select the range of inventory items to calculate by selecting a product category and enable the Include Subfolders option.

-

Enter a Range of inventory items or select All Inventory Items.

-

Select a specific Warehouse if multiple locations are involved. Click Next to continue.

-

Enter the Number of months supply that you wish to keep on hand. Entering 1.0 will calculate minimum and maximum amounts based on inventory supply for one month.

-

Enter the volume settings as shown above. Fill in the details for this boxed section: Based on an average ___ volume for ___ months ending ___ ___. (For the first option, select Sales or Purchases to determine the average volume. Then enter the total number of months and specify the ending month and year.)

The minimum inventory settings can be set based on the average sales or purchase history of the past user-specified months. If the product sales or purchases vary substantially between months, increase the number of months for a better average. If product sales are seasonal, a 12-month sales volume average will be more helpful than a 3-month average. (For example, the sales volume for garden rakes looks very different in winter versus spring. Looking only at winter sales would result in a very low average, but looking only at spring sales would artificially inflate the average. Averaging a whole year of sales will balance out the seasonal differences.)

-

Check the Calculate Minimum to set the Minimum stock level quantities within each item. If this amount is not calculated and is set to zero, the system will not prompt the user to reorder till the count is below zero. Set the formula to the desired equation based on the average month's supply.

-

Turn the Calculate Maximum switch ON to set the Maximum setting within the count tab of each inventory item. The system will also order the Reorder Increment amount whenever the Net Count falls below the Minimum setting. Note that all these count and order settings are found in the product record Count tab.

-

Click on the Calculate button to begin minimum and maximum stock level settings.

Repeat these steps for any other folder groups.

Advanced Inventory Utilities

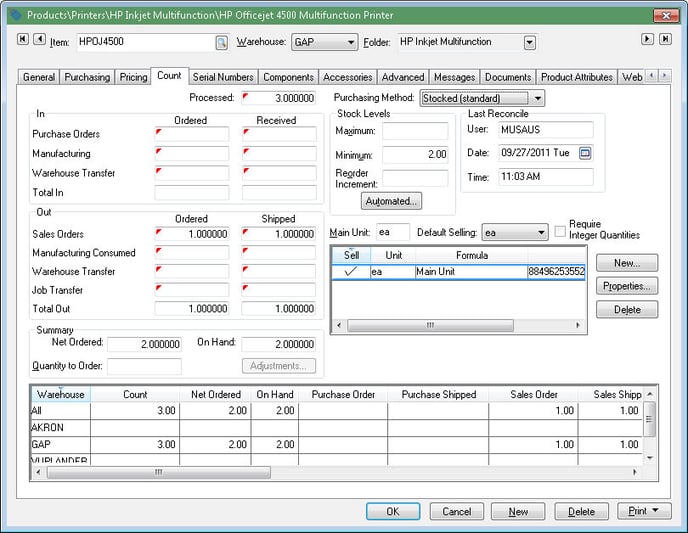

The Advanced Inventory Management tool adds the ability to set the Stock Levels within the product record Count tab based on sales history and projections. This powerful tool automates the process of projecting inventory Stock Levels and recording them within the Count tab of individual product records. Open an inventory product record and click on the Count tab as shown below:

Click on the Automated button below the Stock Levels section in the product record Count tab to set the following settings. (Note that the Automated button will only appear if the optional EBMS modules are installed. If you are interested in these features, please contact your Koble Systems account manager.)

Review the Inventory Forecasting Management for details on this tool.