Manufacturing Batch Status

The manufacturing batch status setting is used to identify the status of the manufacturing process for the current batch. These user-defined status settings may define the multiple steps within the manufacturing process.

Status Options

Complete the following steps to create or change the manufacturing batch status list:

-

Select Inventory > Options from the main EBMS menu and click on the MFG Status tab as shown below:

-

Add Status options to the list. Use the Ctl + Insert or Ctl + Delete keys to delete or insert Status options.

-

Click on the Move Up or Move Down buttons to order the manufacturing Status settings into chronological order according to the manufacturing process. Click OK to save.

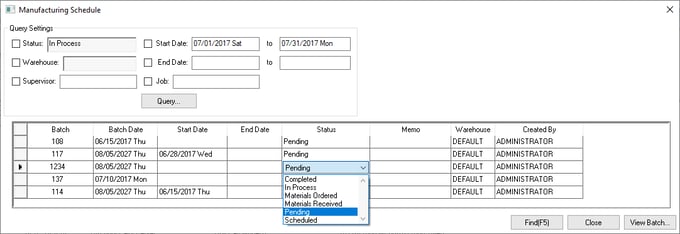

Setting a Batch Status

Open Inventory > Manufacturing batch or the Inventory > Manufacturing Schedule from the EBMS menu to set the Status settings.

Manufacturing batches can be queried by Status Query Settings within the Manufacturing Schedule dialog.

Review Scheduling a Manufacturing Batch for more details on the Manufacturing Schedule dialog.

Review Edit or Print a Batch of Manufacturing Documents for more details on changing batch settings.