Separate Out G/L Cost and Pricing Cost Values for Manufactured Goods

EBMS allows the user to calculate and maintain two different values for finished goods that are manufactured within the batch screen. These different values are useful when the user does not want to increase the inventory General Ledger asset value recorded within the General Ledger with costs that have been expensed, such as labor or miscellaneous costs. Do not use this option without consulting your accountant or an EBMS financial consultant.

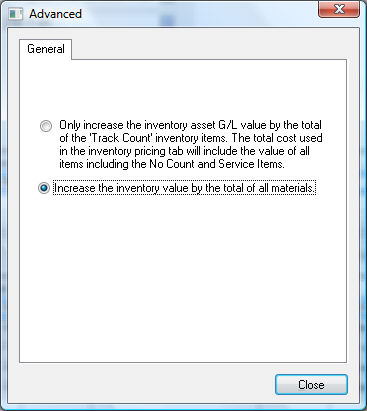

The book value (G/L) cost column and (Pricing) columns will not appear unless the "Only increase the inventory asset G/L value by the total of the 'Track Count' inventory items. The total cost used in the inventory pricing tab will include the value of all items including the No Count and Service Items." option is selected.

Select the View > Advanced option from the menu on the Manufacturing batch window to set this option.

The value of this setting is copied from a global setting when the inventory batch is created. Go to Inventory > Options and click on the Manufacturing tab to set the default global setting as shown below:

The "Only increase the inventory asset G/L value by the total of the 'Track Count' inventory items. The total cost used in the inventory pricing tab will include the value of all items including the No Count and Service items" option should only be used if the cost used for pricing purposes is more than the book value posted to the General Ledger.

This option will cause a pair of costs columns (Cost (G/L) and Cost (Pricing) to appear within the Inventory > Manufacturing window as shown below:

When the first option is selected, the Costs (G/L) columns found within the manufacturing batch screen will only include the value of ‘track count’ items (items classified as Track Count or other perpetual items).

Items classified as ‘No Count’ or ‘Service’ will not be included in the Cost (G/L) and the Total Cost (G/L) totals but are included in both the Cost (Pricing) and Total Cost (Pricing) columns.

Important note: The recommended setting for normal situations is the Increase the inventory value by the total of all materials option found in Inventory > Options > Manufacturing tab.