-

Client Resources

-

EBMS Main Documentation

- Introduction

- Getting Started

- Getting Started | Initial Installation

- Getting Started | Company Setup

- Quick User Guide | Financial Staff | Accountant

- Quick User Guide | Financial Staff | Accountant | Accountants Journal

- Quick User Guide | Sales Staff

- Quick User Guide | General Staff

- Features

- Reports

- Security

- Server Manager

- Technical

- Technical | Data Import and Export Utility

- Technical | SQL Mirror

- Automotive

- Automotive | Parts Catalog

- Automotive | Pricing

- Automotive | Point of Sale

- Automotive | Product Application

- Automotive | Keystone Interface

- Metal Supply

- Fuel Sales

- Horticulture

- Horticulture | Farm Setup

- Horticulture | Processing Payroll

- Horticulture | Managing the Farm

-

Sales

- Introduction

- Customers

- Customers | Miscellaneous Customers

- Proposals

- Proposals | Processing Proposals

- Proposals | Sets and Templates

- MyProposals

- MyOrders

- Sales Orders

- Invoices

- Materials Lists

- Sales and Use Tax

- Sales and Use Tax | TaxJar

- CRM

- CRM | Auto Send

- Recurring Billing

- Credits

- Customer Payments

- Payment Card Processing

- Payment Card Processing | Gift Cards

- Payment Card Processing | Loyalty Cards

- Payment Card Processing | Verifone Gateway

- Freight and Shipping Tools

- General Ledger Transactions

- Point of Sale

- Point of Sale | Point of Sale Hardware

- Point of Sale | Xpress POS System

- Point of Sale | Advanced Tools

- Signature Capture

- Salesperson Commissions

-

Inventory

- Product Catalog

- Product Catalog | Using Product Codes for No Count Items

- Product Pricing

- Product Pricing | Special Pricing

- Tracking Counts

- Unit of Measure

- Purchasing

- Special Orders and Drop Shipped Items

- Receiving Product

- Barcodes

- MyInventory and Scanner

- Components (BOM) and Accessories

- Components (BOM) and Accessories | Component Formula Tool

- Made-to-Order Kitting

- Configure-to-Order Kitting

- Multiple Inventory Locations

- Multiple Inventory Locations | Creating Locations

- Multiple Inventory Locations | Using Multiple Locations

- Multiple Inventory Locations | Product Catalog Sync

- Multi-Vendor Catalog

- Serialized Items

- Serialized Items | Purchasing or Manufacturing an Item

- Serialized Items | Selling and/or Associating an item with a customer

- Lots

- Product Attributes

- Product Attributes | Selling and Purchasing Items with Attributes

- Product Attributes | Custom Attributes

- Mobile Scanner (Legacy)

-

Labor

- Getting Started

- Workers

- Taxes and Deductions

- Work Codes

- Time and Attendance

- Time and Attendance | Time Track App

- Processing Payroll

- Closing the Payroll Year

- Processing Payroll - Advanced

- Salaried Pay

- Piecework Pay

- Direct Deposit

- 3rd Party Payroll Service

- Subcontract Workers

- Flag Pay

- Prevailing Wages

- MyDispatch

- MyTasks

- MyTime

- MyTime | Communications

- MyTime | Setup

- Tasks

- Tasks | Getting Started

- Tasks | Creating Tasks

- Tasks | Scheduling Tasks

- Tasks | Customizing Task Views

- Tasks | Managing Tasks

-

Financials

- Introduction

- Fiscal Year

- Chart of Accounts

- Budget

- Financial Reporting

- Transactions and Journals

- Transactions and Journals | Journals

- Account Reconciliation

- 1099

- Departments and Profit Centers

- Fund Accounts

- Bank Accounts

- Bank Feed

- Vendors

- Vendors | Miscellaneous Vendors

- Purchase Orders

- Expense Invoices

- Vendor Payments

- AP Transactions

- Landed Cost

- Fixed Assets and Depreciation

- Fixed Assets and Depreciation | Fixed Assets

- Fixed Assets and Depreciation | Fixed Assets | Adding Assets

- Fixed Assets and Depreciation | Processing Depreciation

- Fixed Assets and Depreciation | Disposing Assets

- MyJobs

-

E-commerce

-

Rental

-

Job Costing

-

Manufacturing

Creating Lots

Lot records are identified by a lot number that is manually assigned by the user or automatically assigned by the software. Other information such as the Lot Date can also be assigned manually or by the system.

Create Lot Product

Lot records are created by completing the following two steps:

-

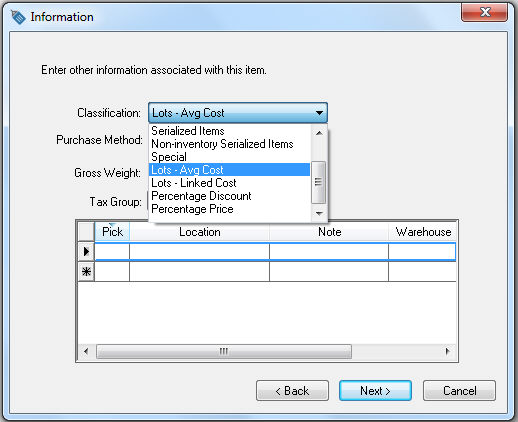

Create an inventory item that is classified using of the following Lots classifications.

-

Create an inventory item with a Classification of Lots - Ave Costs or Lots - Linked Costs as shown in the new inventory wizard example below. Review the Lots Overview section for more details on the Lots Classification.

-

Complete the new inventory item wizard. Review the Product Catalog > Entering New Products section for more details.

-

Enter a new lot number into the purchase order or manufacturing batch - A new lots record is created as soon as a unique Lot Number is associated with a purchase or newly manufactured item. The On Hand quantity is incremented on an existing lots record if an existing lot number is entered into the PO or batch.

Purchase Lot Product

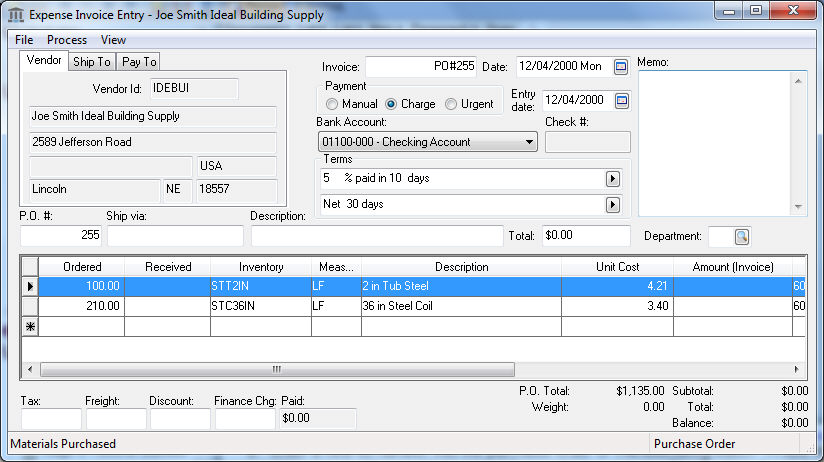

Complete the following steps to record the purchase of product that includes a lot number or date. Review [Financials] Purchase Orders > Entering a New Purchase Order for instructions on creating purchase order detail lines.

-

Open a purchase order as shown below:

-

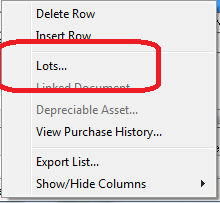

Right click on either of the purchase order details lines since both the STT2IN and STC36IN are classified as Lots and the following context menu will appear:

-

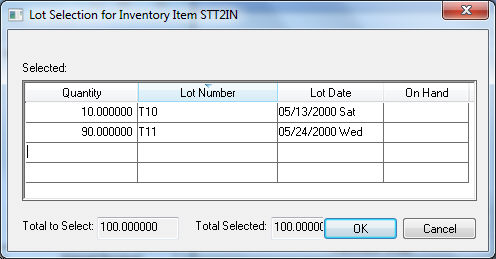

Click on the Lots option on the context menu to open the Lot Selection dialog as shown below:

-

The Quantity will default from the purchase order. Change the Quantity value if the purchase order line involves multiple Lot Numbers.

-

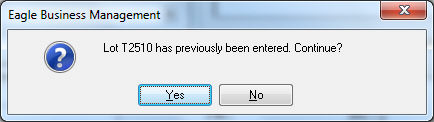

Enter a required Lot Number or code. If the Lot Number is not unique a warning message will appear.

-

Click Yes to increment the On Hand amount by the Quantity count rather than creating a new lot record.

-

Click the No button to change the Lot Number to a unique number or code.

-

Enter an optional Lot Date. Multiple dates can not be assigned to the lot record.

-

Click OK to record lot information.

Note that the Lots information must be entered before the purchase order is processed into an invoice. Review [Financials] Expenses Invoices > Processing an Invoice for more details on processing a purchase order into an invoice and updating inventory values.

New Lots records can also be created by manufacturing Finished Goods that are classified as Lots. Right click on the Finished Goods lines within a manufacturing batch and select Lots from the context menu. The Lots Selection dialog and entries are similar to the purchase order options explained in this section. Review the Manufacturing > Creating a Batch > Creating a Simple Batch section for more details on creating and processing a manufacturing batch.

Lot Options

-

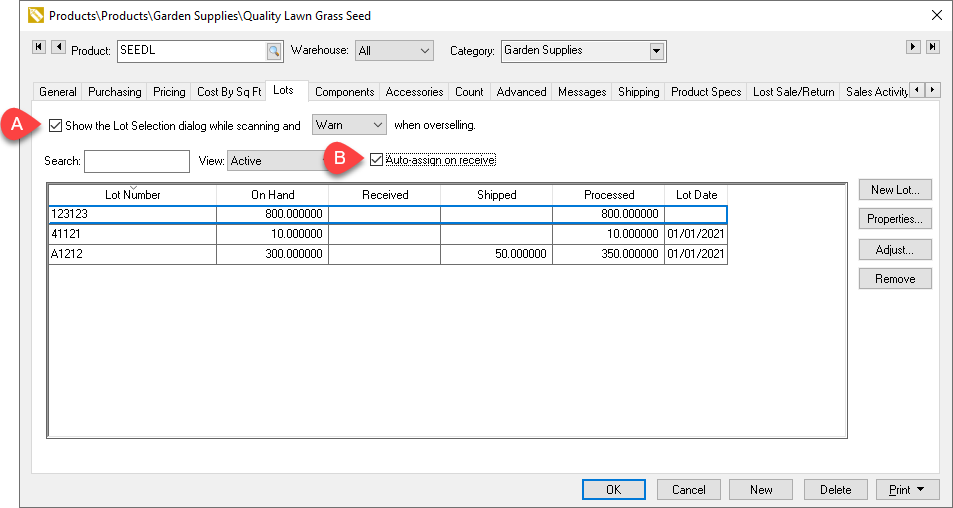

Enable the Show the Lot Selection dialog while scanning and Warn/Block when overselling to limit sales when stock levels for a lot are low. Set the Block option to bar a user or Warn option to only warn.

- The Lot Number and Lot Date can be automatically assigned by enabling the Auto-assign on receive option located on the Lots tab of the inventory item as shown below:

Review the Product Catalog > Changing and Item Classification for instructions to changing the Classification to a lots classification.