- EBMS Knowledge Base

- Manufacturing

- Processing a Manufacturing Batch

-

Client Resources

-

EBMS Main Documentation

-

Sales

- Customers

- Proposals

- Proposal Sets and Templates

- Sales Orders

- Sales Invoices

- Materials Lists

- Sales and Use Tax

- TaxJar

- Recurring Billing

- Customer Credits

- Customer Payments

- Card Processing and Koble Payments

- Gift Cards and Loyalty Cards

- Verifone Gateway and Point Devices

- Freight and Shipping

- General Ledger Transactions for Sales

- Point of Sale and XPress POS

- Point of Sale Hardware

- Salesperson Commissions

-

Inventory

- Product Catalog

- Using Product Codes for No Count Items

- Product Pricing

- Special Pricing

- Tracking Inventory Counts

- Unit of Measure (UOM)

- Purchasing Stock

- Special Orders and Drop Shipped Items

- Receiving Product

- Barcodes and Inventory Scanners

- Components, Accessories, and Bill of Materials

- Component Formula Tool

- Made to Order Kitting (MTO)

- Configure to Order Kitting (CTO)

- Multiple Locations: Warehouses, Divisions, Departments

- Sync Product Catalogs between Companies

- Vendor Catalogs

- Serialized Items

- Lots

- Product Attributes

-

Expenses

-

Labor

-

Financials

-

Tasks and Work Orders

-

Job Costing

-

Manufacturing

-

Rental

-

Apps

-

E-commerce

-

EBMS Automotive

-

EBMS Horticulture

-

EBMS Metal Supply

-

EBMS Fuel Sales

Processing a Manufacturing Batch

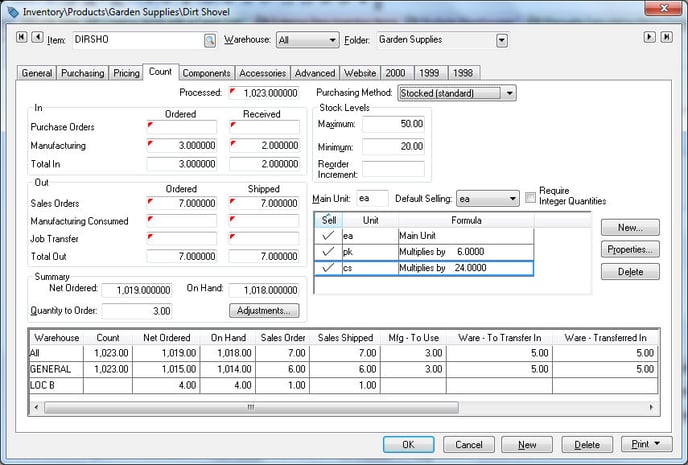

Inventory general ledger transactions are not created until a batch is processed. The only inventory counts affected by batch entry before the process are the Manufacturing fields located in the Inventory > Product Catalog > Count tab as seen below:

These manufacturing fields are affected in a similar manner as the S.O. and P.O. values contained in the Count tab. A batch can be changed or deleted as long as the batch is not processed.

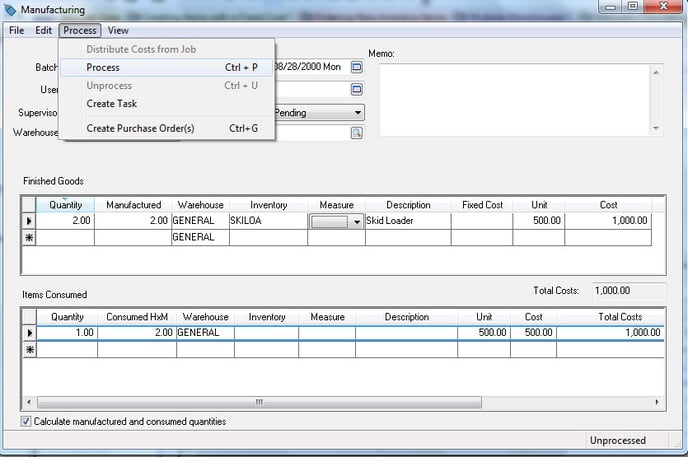

A batch is processed within the manufacturing window as shown below:

A batch should not be processed until the manufacturing process is completed. Select Process > Process from the manufacturing window menu to process a batch. An alternate way of processing is by hitting the CTL + P keys on the keyboard.

The process step affects the following information.

-

The Completed Date will be set to today’s date if the entry is blank.

-

The Status field within the manufacturing window will be set to Completed. Review the Batch Status section for more details on the manufacturing status options.

-

The inventory Count for all Finished Goods will be incremented and the manufacturing fields within the Inventory > Product Catalog > Count tab will be decreased.

-

The inventory Count for all Items Consumed are decreased and the manufacturing fields within the Inventory > Product Catalog > Count tab will be decreased.

-

The following general ledger transactions are created if the Inventory > Options > General tab > Inventory Method option is set to Perpetual

General Ledger Account of Finished Good items Debit / Credit

- Inventory asset account of each Finished Good that is being manufactured - Debit

- Inventory variance account within Finished Good item + department code from the Purchase G/L code - Credit

General Ledger Account of Items Consumed Debit / Credit

Track Count Items

- Inventory asset G/L account - Credit

- Inventory Variance account of finished goods - Debit

No Count and Service Items

- Inventory Manufacturing Offset - Credit

- Inventory Variance account of finished goods - Debit

No Inventory Item

All General Ledger Accounts are found in the Advanced tab of the Inventory Item.

The general ledger transactions must be posted from the inventory module before the general ledger account balances or the inventory history year pages are updated.

This optional EBMS module is not included on all versions of the EBMS software. Review [Main] Features > Optional Features > Optional EBMS modules for specific instructions used to identify or add optional modules.