An important part of the sales and inventory management process is to reserve inventory for a specific order. This removes the product from available inventory that can be sold. A simple implementation of this process is to remove the product from the store shelf.

A consistent process for reserving inventory or staging product within sales orders can help companies properly fulfill orders and maintain accurate inventory counts. Since this stage falls between creating a sales order and processing it into a sales invoice, it is sometimes difficult to keep track of what inventory is promised to which customer. Fortunately, EBMS provides ways to manage these interim inventory steps.

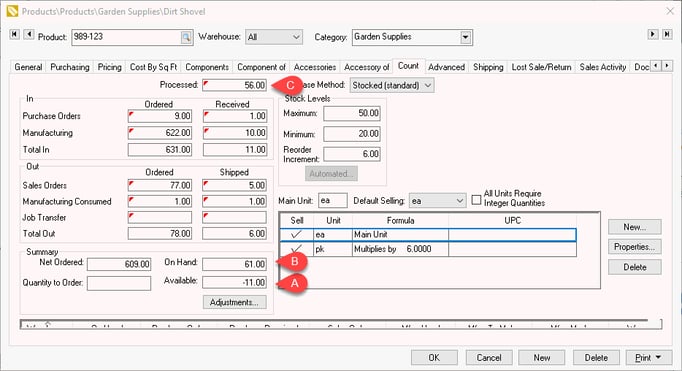

EBMS includes the tools to reserve inventory using one of the following totals found in the product record Count tab:

-

Available: Orders are reserved when sales orders are entered into EBMS. This method is used most frequently when inventory stock is high, and most sales are sold from stock. (This value can be found in the Summary section of the product record Count tab.)

-

On Hand: Orders are reserved by populating the Shipped amount in the sales order. This is the most common method used in EBMS, when orders are placed in a sales order and the order pick up or delivery is done at a later time. (This value can be found in the Summary section of the product record Count tab.)

-

Processed: Orders are reserved when the sales invoice is processed. This method is used for most point-of-sale environments where the order and fulfillment are accomplished at the same time. (This value can be found at the top of the product record Count tab.)

Available

This method can be used if orders are fulfilled in a first come, first served basis. Product is reserved when a sales order is created. This method is normally used when inventory stock levels are high and there are not many special orders or other non-stock product sales.

Complete the following steps to use this method of product reservation:

-

Select one of these Available count formulas from the Available Quantity Calculation within as shown below.

Both options reserve product when a sales order is entered. The Shipped column does not change what is available, since the quantity within the Ordered column reduces the amount available. The difference in the following options is based on when to increase the amount available.-

Processed Count + Incoming Received - Outgoing Ordered: Product is not available until the product is marked as received within the purchase order.

-

Processed Count + Incoming Ordered - Outgoing Ordered: Product is available as soon as the purchase order is entered. This option should only be used if the delivery time between the time that the product is ordered in the purchase order and the time that the product is available to sell is insignificant.

-

-

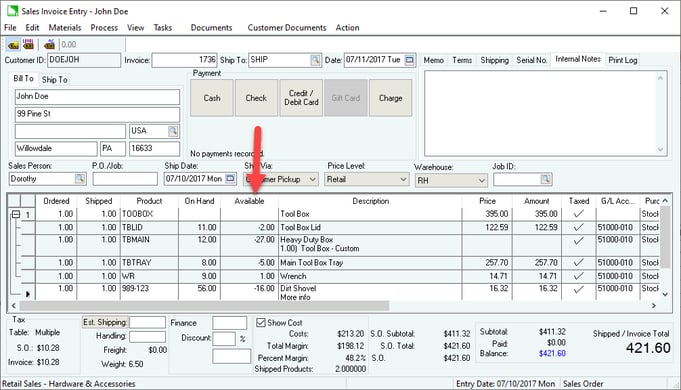

Display the Available column within the sales order, since the Warn when inventory is low option (which can be set within the ) is designed for the On Hand method of reserving product.

Review Column Appearance for instructions to show the Available column.

On Hand

Reserving product when items are pulled from inventory is the most common method used within EBMS. On Hand inventory reservation is used when orders are placed in a sales order and the order pick up or delivery is done at a later time.

Many of the default settings within EBMS are designed for the On Hand method. Review the following settings to implement it:

- Implement a good receiving process: The On Hand method requires the user to implement a proper receiving process that populates Received within the purchase order and Shipped within the sales order immediately as product is placed into or removed from inventory. Review Inventory Receiving Overview for instructions to implement a receiving process that uses the On Hand reservation process.

- Go to to enable the Warn when inventory is low option to prompt the users when inventory is reserved or is not in stock. (This option is the first option in the User Preferences section.)

- Implement a special order process for purchases prompted by customer orders.

- Use the Sync Quantities special order purchase method to stage all special orders within a sales order by automatically matching the Shipped quantity within a sales order to the Received quantity within the purchase order.

- Use the Associated special order purchase method to manually populate the shipped quantity in the same manner as other track count items. Review Purchasing Special Orders for more details on staging special orders.

The following values adjust the On Hand amount to indicate the quantity of product available.

Processed

For the Processed method, orders are reserved when the sales invoice is processed. This method is used for most point-of-sale environments where the order and fulfillment are accomplished at the same time.