- EBMS Knowledge Base

- Labor

- Piecework Pay

-

Client Resources

-

EBMS Main Documentation

-

Sales

- Customers

- Proposals

- Proposal Sets and Templates

- Sales Orders

- Sales Invoices

- Materials Lists

- Sales and Use Tax

- TaxJar

- Recurring Billing

- Customer Credits

- Customer Payments

- Card Processing and Koble Payments

- Gift Cards and Loyalty Cards

- Verifone Gateway and Point Devices

- Freight and Shipping

- General Ledger Transactions for Sales

- Point of Sale and XPress POS

- Point of Sale Hardware

- Salesperson Commissions

-

Inventory

- Product Catalog

- Using Product Codes for No Count Items

- Product Pricing

- Special Pricing

- Tracking Inventory Counts

- Unit of Measure (UOM)

- Purchasing Stock

- Special Orders and Drop Shipped Items

- Receiving Product

- Barcodes and Inventory Scanners

- Components (BOM) and Accessories

- Component Formula Tool

- Made-to-Order Kitting

- Configure-to-Order Kitting

- Multiple Locations: Warehouses, Divisions, Departments

- Sync Product Catalogs between Companies

- Vendor Catalogs

- Serialized Items

- Lots

- Product Attributes

-

Expenses

-

Labor

-

Financials

-

Tasks and Work Orders

-

Job Costing

-

Manufacturing

-

Rental

-

Apps

-

E-commerce

-

EBMS Automotive

-

EBMS Horticulture

-

EBMS Metal Supply

-

EBMS Fuel Sales

Collecting Piecework Details using Time Track

The Time Track app is a convenient tool to allow users to record the quantity of piecework units using a Windows 10 touch screen device, such as a tablet. Time Track can be used as a time clock replacement that gives the user the ability to record the following information along with the clock in and clock out times:

-

Allocate time for multiple work codes during the clock out process: Review Time Track App > User Configuration to configure a worker with multiple work codes that will be allocated during the clock out process.

-

Record piecework quantities: Continue with the following steps to configure this option.

Configuring a Worker to Record Piecework

-

Set up the worker record: Review Entering New Workers if the worker record has not already been created.

-

Configure the app settings for Time Track by completing the following steps:

-

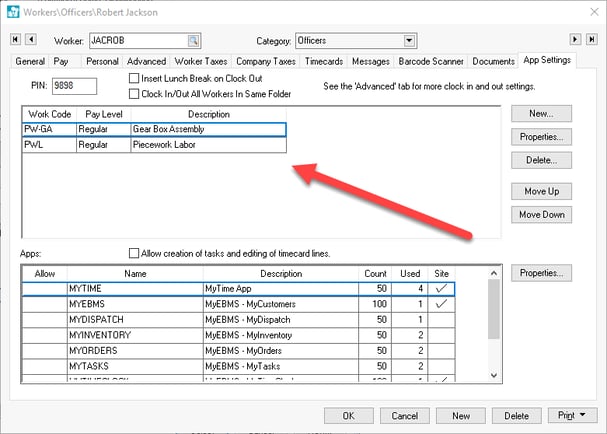

Open a worker record by going to Labor > Workers and double-clicking on a worker ID to open the record. Go to the worker record App Settings tab as shown below:

-

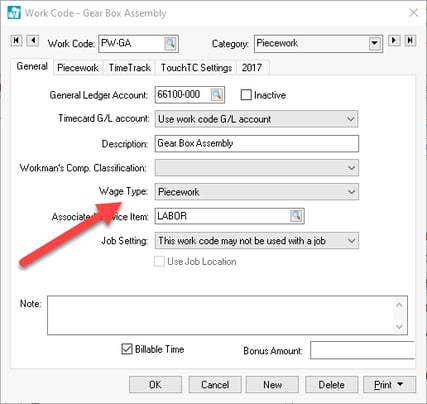

Add only Work Codes in the App Settings tab that have a Wage Type of Piecework. Note that work codes with a wage type of Standard Wage and Piecework may not be listed within the same worker's work code list. Review Work Codes Overview for configuration of the wage type.

Review Time Track App > User Configuration for instructions to add piecework work codes to the worker's app settings tab. -

Launch the Time Track app.

-

Clock into Time Track using the same steps as logging time. Review Time Track Overview for steps to log in.

-

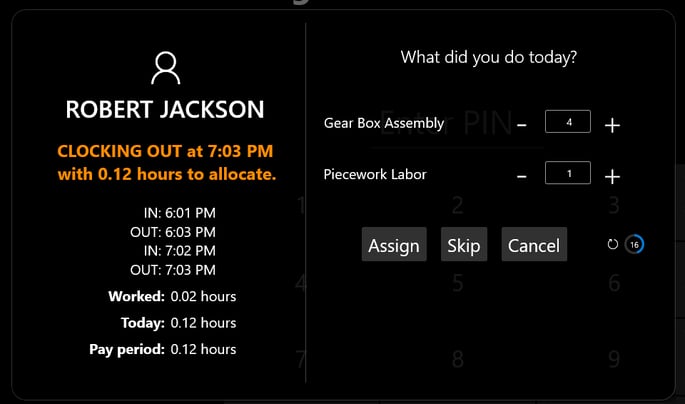

The following piecework options appear when clocking out using Time Track.

-

Click on the minus (-) or plus (+) symbols next to Piecework Labor to populate the quantity of piecework completed during the time period since the last clock in.

-

Repeat for multiple piecework codes.

-

Click Assign to record quantities. Note that the quantities will be saved when the timer expires.

Review Time Track Overview for more details on using Time Track.