Low Inventory Processing for Manufacturing

Low inventory processing tools facilitates the ability to create one or multiple manufacturing batches based on low inventory prompts within an order.

A product is flagged as low inventory when all of the following are satisfied:

-

The detail line that contains the product is not linked to another document using special order tools

-

The Ordered, Shipped, or Quantity is greater than zero.

-

The product Classification is listed as Track Count, Serialized, or Lots but not Special.

-

If On Hand + "saved" Shipped is equal to zero, then Net Order + "saved" quantity is less than current amount entered. Otherwise On Hand + "saved" Shipped is less than current Shipped. ("saved" means the value is already saved in the database for this line.)

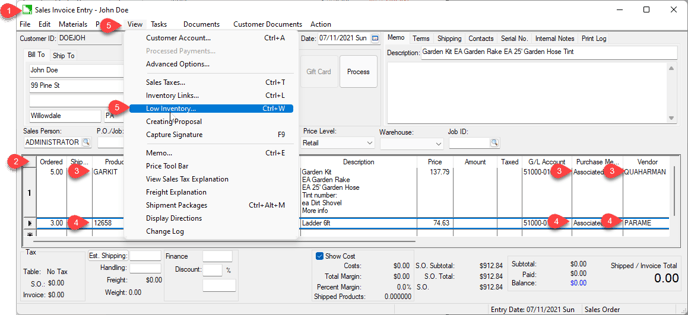

Complete the following steps to launch the Low Inventory process:

Step #1. Identify Finished Goods with Low Stock

-

Open a sales order. Orders can be queried using batch processing based on the ship date, product contents, or unscheduled orders. Review Order Management using Batch Processing at the end of this section for configuration options.

-

Products that are managed within the low inventory process must have the Classification of Track Count, Serialized, or Lots.

-

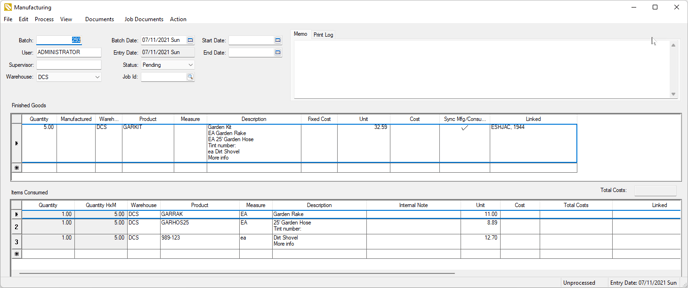

Verify that the product being manufactured has the Purchase Method set to Associated and the Vendor set as a Manufacturing Vendor. Set these settings within the product's Count tab to default the Purchase Method and the Primary Vendor within the product's Purchasing tab. (Example: See first line in the image above.)

-

Verify that the product being purchased has the Purchase Method set to Associated or another special order setting and the Vendor set to the purchasing vendor. (Example: See second line in the image above.)

-

Select View > Low Inventory from the sales order menu.

-

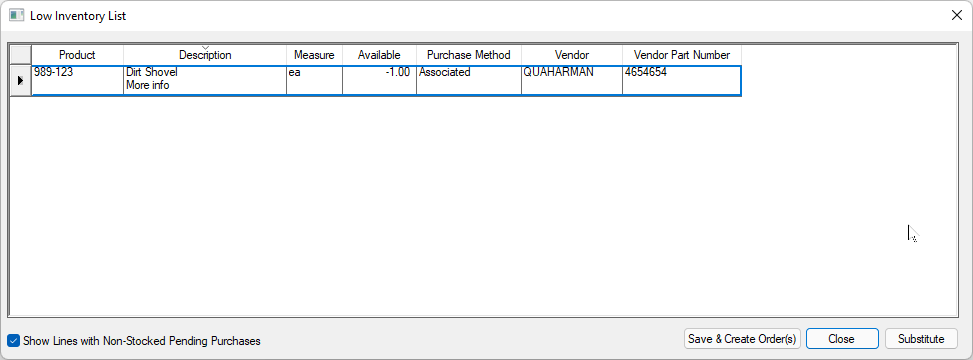

Verify that the Vendor setting is set to a manufacturing vendor for products being manufactured and the purchasing vendor for items being purchased. Review Set Up the Manufacturing Process as a Generic Vendor for manufacturing vendor configuration details. Review Purchasing Tab for details on configuring the primary vendor.

-

Enable Show Lines with Non-Stocked Pending Purchases to include items with low inventory but already contain a purchase order or manufacturing batch to cover the stock requirements.

-

Click Save & Create Order(s) to create a manufacturing batch for the manufacturing items and purchase orders for the items being purchased. Continue with the next step to continue with the material planning process.

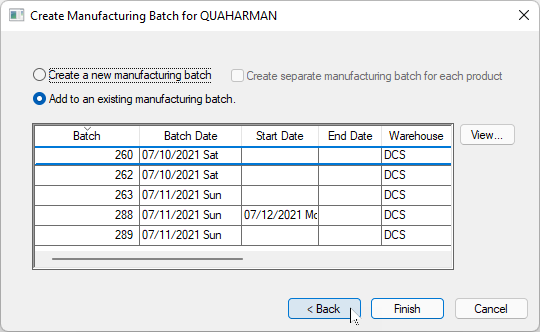

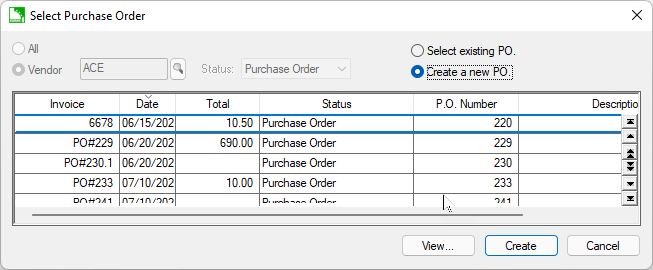

Step #2. Create Batches and Purchase Orders

-

The Low Inventory List menu option can be found within sales order, MTO order, or manufacturing batch dialogs.

-

The following dialogs will open when the Save & Create Order(s) button is selected based on the type of Vendor:

-

The Create Manufacturing Batch dialog will appear for Manufacturing Vendors.

-

The Select Purchase Order dialog will appear for purchasing Vendors.

-

-

Multiple sub-Low Inventory List dialogs may appear if the MRP process includes multiple levels.

Step #3. Schedule Batches and Sales Orders

-

Set the ETA Dates of the raw materials or parts required to manufacture the sub-batches and the finished goods batches.

-

Schedule the manufacturing batch schedules starting with the sub-batches and then setting the finished goods batches and sales order schedules.

-

Review Schedule Manufacturing Dates for manufacturing schedule date options.

-

Review Batch Billing Overview to list orders based on the ship date.

-

Review and Adjust Schedule and Materials Plan

A materials resource plan is monitored and adjusted as the schedules progress. Review Sankey Diagram for a sample manufacturing plan.

Order Management using Batch Processing

EBMS contains an order management tool to conveniently list sales orders based on certain criteria.

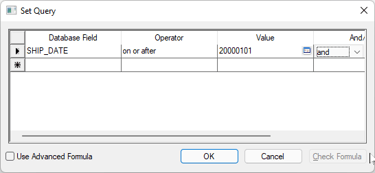

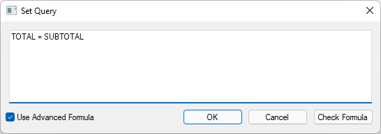

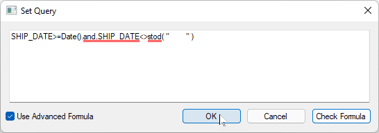

Configure the following query settings within Sales > Batch Processing dialog to group orders:

-

Unscheduled orders: This Sales Order Query is set to list orders with no ship date indicating that scheduling needs to be done.

-

Orders that are complete and ready for shipment: This Sales Order Query is set to show all orders that are fully shipped.

-

Orders that are past the estimated ship date: This Sales Order Query is set to only show orders that are beyond the ship date.

ReviewBatch Billing Overview for query setup and batch process options.

Prerequisites

The following settings should be configured before using the low inventory process for manufacturing resource planning:

The Warn when inventory is low setting should be properly set for each user that does sales order entry. This user-based setting is found in the Sales > Options > Invoices and S.O.s tab. Disable this option if the order entry staff does not get involved in the manufacturing planning process. Disable the Include non-stocked purchase methods with low inventory warning option to only show warning for stock items and not special order items.