Set Up the Manufacturing Process as a Generic Vendor

The manufacturing process can be automated by setting up an internal vendor record as a generic manufacturing vendor. This feature is used to identify the manufacturing process as the source of a product instead of a primary purchasing vendor.

Create Internal Manufacturing Vendor

Complete the following steps to create an internal manufacturing vendor:

-

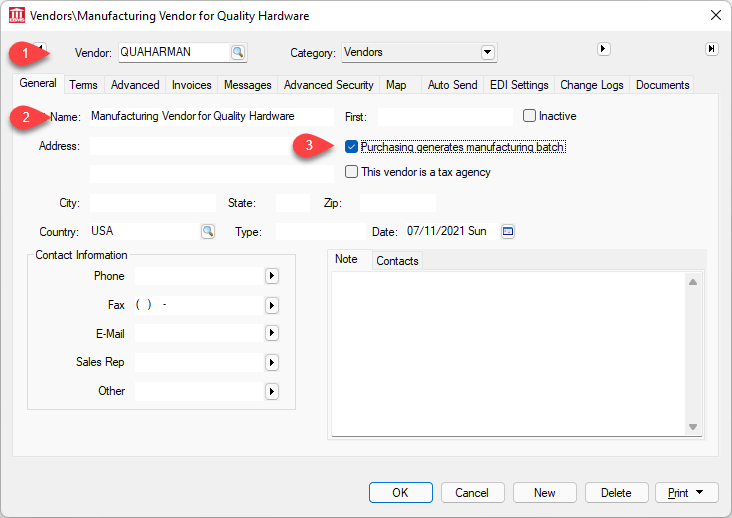

Create an internal vendor using the company name as shown below. In this example, the Name is Manufacturing Vendor for Quality Hardware.

-

Enable the Purchasing generates manufacturing batch option on the vendor record General tab, as shown above. This option identifies this vendor as the internal manufacturing vendor. (Note that this option should not be enabled for any manufacturing vendors that sell product to the company.)

-

Enter a Vendor ID that identifies the internal vendor. Review Changing Vendor Information for steps to create or change vendor information.

Set the Primary Vendor as Manufacturing Vendor

Complete the following steps to identify product that is manufactured using batches, rather than purchased using purchase orders. A group of products can be set Changing Inventory Defaults.

-

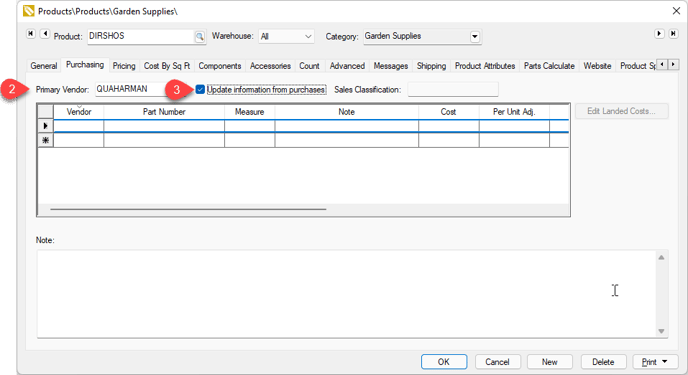

Open a product record and click on the Purchasing tab. (To open a product record, open Inventory > Product Catalog and double-click on a product in the list.)

-

Set the Primary Vendor to the internal manufacturing vendor with Purchasing generates manufacturing batch option enabled.

-

Enable the Update information from purchases option to keep last costs updated. Review Purchasing Tab for more information on the sourcing of product.

Create Manufacturing Batch instead of Creating Purchase Orders

Product must be classified as Track Count, Serialized Items, or Lots to increase inventory using manufacturing.

Review the following documentation for steps to create manufacturing batches when inventory is low.

-

Review Low Inventory Processing to create batches from the low inventory dialog.

-

Review Inventory Purchasing Page to create batches when stock levels are below minimum stock.

-

Review Purchasing Special Orders to create batches for special orders.