Planning Materials for Manufacturing

Planning out necessary materials and resources is an important aspect of the manufacturing process. A procurement plan for the raw materials, parts, or sub-assemblies is required to manufacture finished goods, such as equipment, mixes, and other kits or assemblies.

The EBMS software contains many tools to respond to low inventory stock levels or to special order products needed in the manufacturing process. These tools are used to purchase raw materials, parts, or other items required to manufacture a product or create a mix. Multiple level batches are created, evaluated, and managed using a Low Inventory Process for Manufacturing.

The following set of processes can be used to create multiple level manufacturing batches. Review the following sections for steps to launch the manufacturing material planning process from these dialogs.

-

Use the Low Inventory Process to manage material planning when the low inventory dialog appears within a sales order or manufacturing batch.

-

Use the Inventory Stock Level Process to manage material planning based on the inventory stock level parameters.

-

The MTO Manufacturing Process allows the user to manage material planning for a specific MTO sales order.

-

Use the Special Order Process to create MRP manufacturing batches based on a finished goods item within a sales order.

Prerequisites

The following steps are important prerequisites before continuing with the materials planning step:

-

Create inventory items within the EBMS product catalog for the finished goods as well as the sub-assemblies or raw material.

-

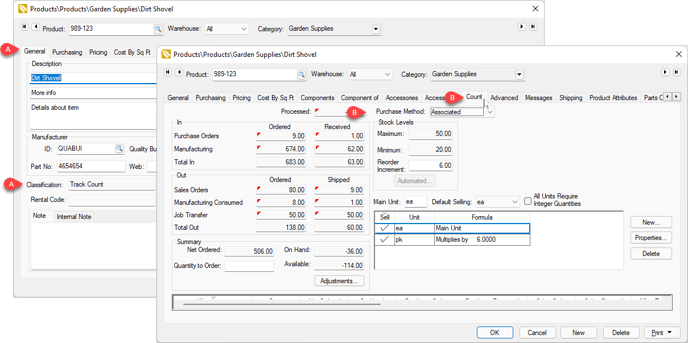

The product Classification should be Track Count, Serialized, or Lot to manage the counts of each level. The Classification field is found on the product record General tab.

-

Set the Purchase Method to Associated within each item. The Purchase Method field is found on the product record Count tab.

Review Entering New Products for more details on creating product records.

-

-

Create a bill of materials (BOM), mix, or component list for the finished item. Some finished goods may require a multi-level BOM. Note that optional components can be configured within a component list. Review Components and Accessories Overview for more details on creating these materials lists.

-

Enable the Sync MFG/Consumed option on the manufacturing batch page. Review Sync Finished Goods Quantities with Items Consumed for information on this option.

Low Inventory Process

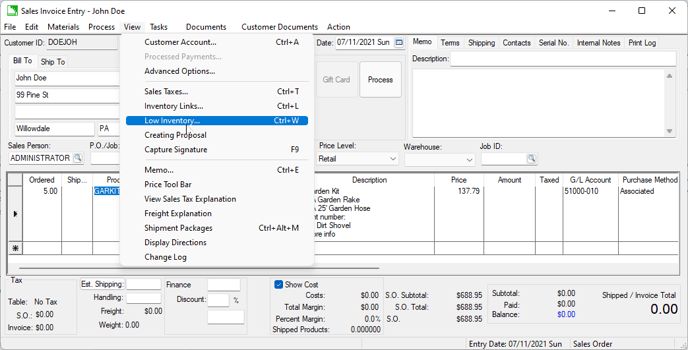

Open a sales order and select View > Low Inventory from the Sales Invoice Entry menu to launch the materials planning process.

Review Low Inventory Processing for process details to manage special orders and other low inventory prompts.

Inventory Stock Level Process

This method uses the Inventory Purchasing Page to prompt the user to create manufacturing batches to replenish the finished goods stock levels. Review the following documentation to use this method:

-

Enter inventory stock level settings for finished goods products: Review Stock Level Settings to review multiple stock level setting options.

-

Configure the generic manufacturing vendor: Review Set Up the Manufacturing Process as a Generic Vendor to setup this required generic vendor settings.

-

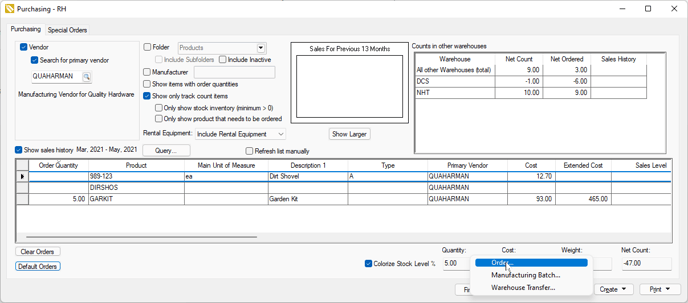

View and process low inventory based on stock level settings using the Inventory Purchasing Page. This process can be used to purchase or manufacture product.

-

Click Create > Order or Create > Manufacturing Batch from the Purchasing page to create the manufacturing batches.

Review Inventory Purchasing Page for steps to configure and use this dialog to create manufacturing batch for stock product that are manufactured as well as purchased. -

The purchasing page will create manufacturing batches which may prompt a low inventory process. Review Low Inventory Processing for the steps available to create multiple level manufacturing batches as well as purchase orders for raw materials and parts.

Made to Order (MTO) Manufacturing Process

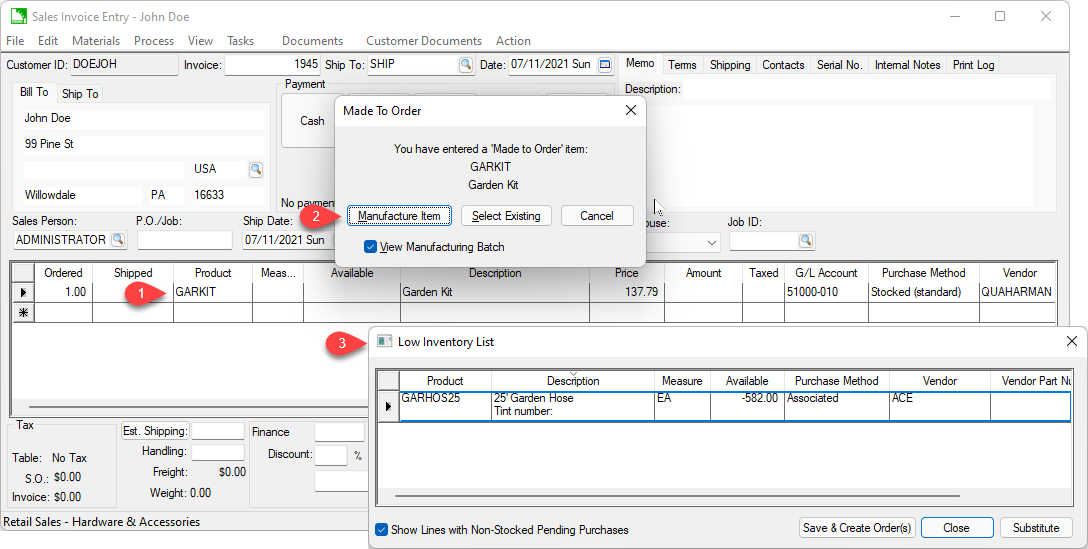

Complete the following steps to launch the MTO Manufacturing process:

-

Enter a MTO item within a sales order: Review Add a Made to Order Item into a Sales Order for steps to create a MTO manufacturing batch within a sales order.

-

Select Manufacture Item from the MTO dialog.

-

The Low Inventory List will appear. Review Low Inventory Process for the steps to create sub-batches or purchase orders as a result of low stock inventory.

Managing a multiple step manufacturing material plan

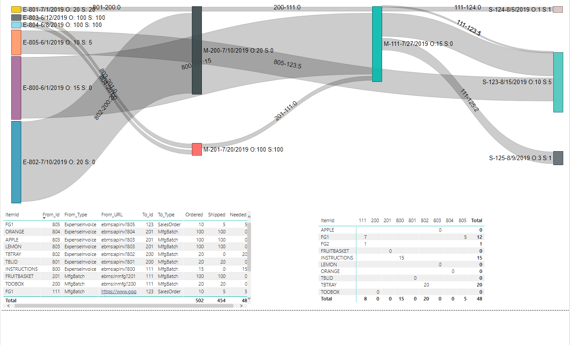

Creating a customized Sankey diagram using a business intelligence tool such as Microsoft Power BI can be a valuable tool to map the entire manufacturing flow from purchases or inventory stock to the sales order. SQL Mirror is required to properly generate an effective Sankey diagram.

Review Sankey Diagram for Manufacturing Processes for diagram samples, setup requirements, and the management options available for this manufacturing process mapping solution.

Additional Resources

Millcreek Manufacturing Testimonial