Using Inventory Components for Manufacturing

A Component List is used to define a standard list of materials used to manufacture a product. A component list can also be referred to as a bill of materials (BOM). The component list may consist of other inventory items or may contain non-inventory items such as raw materials or labor. The predefined component list is an optional entry but can save a considerable amount of time if the materials used for the manufactured goods are consistent.

Creating a Component List (BOM)

Complete the following steps to manufacture a dirt shovel:

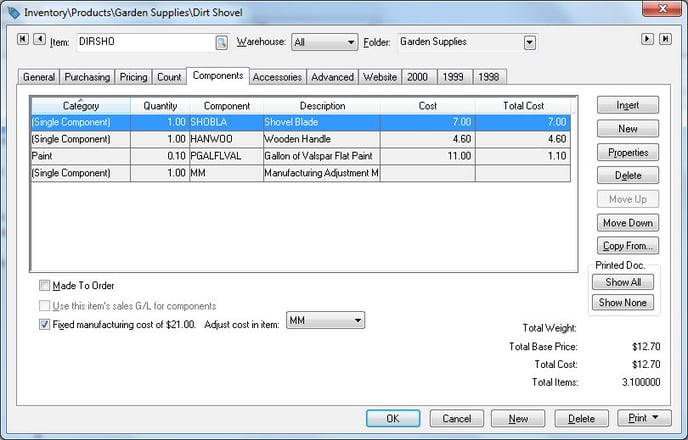

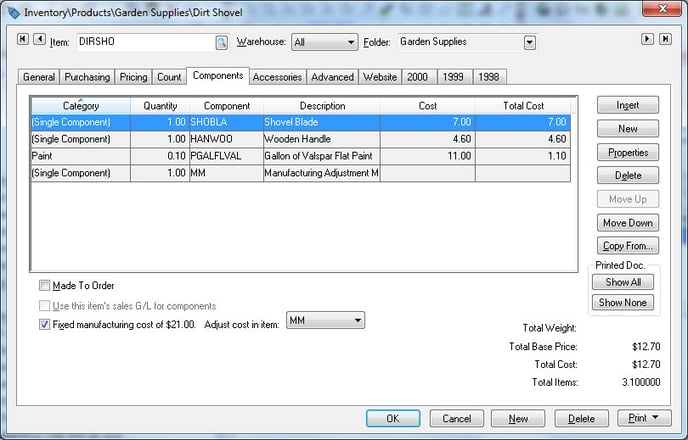

- Open the product record for the inventory item that is being manufactured and click on the Components tab as shown below:

- Click on the New button on the right side of the Components tab to add a new component.

-

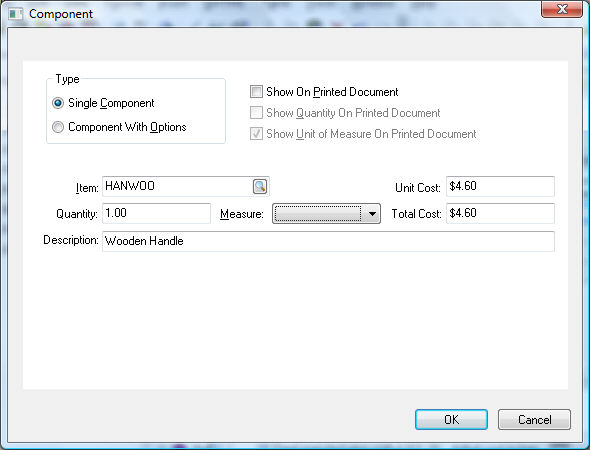

Set the component Type to Single Component option for standard component lists. Review the Optional Components or Accessories section for details on the Component With Options setting.

-

Enter the inventory Item, Quantity of components for each finish goods item, and unit of Measure.

-

The Unit Cost is derived from the Cost value found in the Pricing tab of the item. The Unit Cost and Total Cost cannot be changed within this window. Right-click on the inventory Item entry and click on the lookup option. You can change the cost value in the pricing tab of the component.

-

Click the OK button to add the component.

Click the New button on the right side to add any additional components.

A component list may consist of raw materials or components but may also include fixed labor costs and miscellaneous costs. Review Adding Adding Labor and Other Job Costs to a Manufacturing Batch to a Batch for more details.

The Additional Items option switch should be turned off when components are used within a manufacturing batch.

Review the Creating Manufactured Items with a Fixed Cost section for details on the Fixed manufacturing cost option.

Component List within a Manufacturing Batch

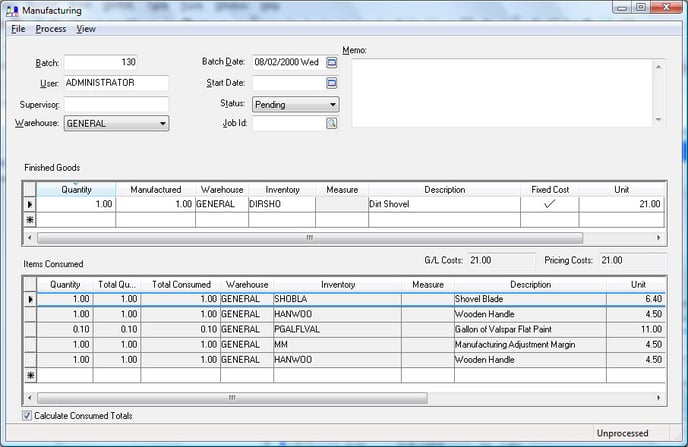

Click OK to save the component list. Go to Inventory > Manufacturing to manufacturing the finished goods (dirt shovel) from the components.

The component list (the list under Items Consumed) can be changed within the manufacturing batch. Any permanent changes must be made within the component tab of the finished goods item. Review Manually Calculating Items Consumed if the components are being recorded for the entire batch rather than per finished good unit.

Note that an item within the materials list may contain components. You can create a component list within the Items Consumed list by selecting any component line that does not contain a ‘track count’ item. Press CTRL + += on the keyboard to create a materials list. The materials list within the Items Consumed list works in a similar manner as the sales invoice. Review Creating an Inventory Unit within the Sales Invoice of the sales documentation for more details.

An EBMS user may wish to display component details within the Description of a serialized item that has been manufactured. This allows the ability to easily search, display, and print the component details from the item description.

To enable this feature, complete the following steps from within the Manufacturing dialog:

Review Sync Finished Goods Quantities with Items Consumed for important setup steps to synchronize data using the component list.

If an EBMS user wishes to always print the component details in the item Description of the Finished Goods this may be defaulted from within the inventory item Component dialog. Review Adding Components to Create an Assembly Kit for information on how to set this default.