Metal Supply Overview

Metal Supply

Integration between quoting, sales, design, manufacturing, and accounting within a metal supply center can save time and increase accuracy. Sales tools allow the user to record individual orders with custom length metal panels, stock and custom trim, metal packages, and more.

EBMS quoting, billing, kitting, serialized coils, variable length inventory, and accounting combined with Variobend design tools streamlines the accounting process of a metal manufacturing. As the business grows, production in the shop must be closely connected with the office to streamline communication, data entry, and work orders. EBMS partners with the metal industry to address these challenges and decrease process time from quote to delivery.

Interface EBMS directly to some of the industry-leading roll form controllers to create an efficient and accurate metal sales process.

Selling Metal

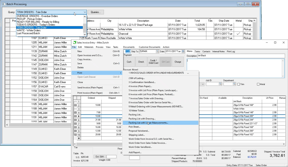

The strength of the EBMS software within the metal industry is the efficiency of creating orders that contain variable length metal panels and trim. The Sales > Batch Processing dialog gives the user to ability to quickly view, print, and process a batch of orders.

Review Batch Billing Overview to set up and configure this tool to batch orders for printing and processing.

Review the following sections for instructions to sell metal products:

Sell Roll Formed Metal Panels

Multiple length metal panels are manufactured from metal coil that can be tracked using a lot number. There are two methodologies for selling roll formed metal panels or steel studs:

-

Stock panels classified as Track Count products: These items are manufactured which tracks metal panel stock.

-

Made-to-order panels classified as No Count products: These items deduct the coil using an invoice materials list which effectively reduces coil stock when the customer is invoiced. (A no count item should not be used for stock metal panels.) Separate items classified as Special can be used for returned metal that is placed in stock. Review Generic Special Order Items for instructions to track count for various sizes or color of panels using a common inventory item code.

Review Roll Formed Metal for setup and process details to manufacture and sell metal panels.

Selling Stock Trim

When the trim or metal check box is checked (order complete) and there are values in the MFG column, it prompts to create a manufacturing batch for those items, to instantly manufacture the quantities shown in the column. Review Instant Manufacturing Batch from Sales Order for instructions to create a batch from an order.

Selling Custom Trim

Equip your sales workers with tools to quote and sell custom trim by style, dimensions, and number of bends. Generate accurate pricing and create orders for manufactured or stock trim packages without tedious manual calculations. Generate drawings using the Variobend Desktop software is ideal to create the specifics of the trim and copy to EBMS.

The EBMS software can be configured to price the custom trim based on girth and bends. Custom trim drawings can be stored in each line item of the order to track details and be displayed on a work order for both the shop and the customer.

This work order form can be used to give instructions to the manufacturing staff or to verify the order with the customer. Review Sales Order Documents for steps to attach a work order to a sales order document.

No Count Stock vs. Made-to-Order Track Count

Roll Formed Metal

There are 2 methodologies for selling roll formed metal panels or steel studs: Track Count, which uses manufacturing to create stock before product is sold and No Count, which uses the materials list feature to reduce coil stock when panels or studs are shipped and invoiced.

| Pros and Cons | Track Count | No Count |

| Finances | Tracks inventory value of metal panels between the time product is manufactured and when it is sold. Review manufacturing stock. | Raw material COGS is processed when panels are sold. Manufactured panels are not inventoried at any time. Review Materials List. |

| Inventory Control | Inventory is maintained for stock panels. | Coil metal is in inventoried until panels or studs are sold. Metal panels stock is not tracked. |

| Managing Part Numbers | Requires a unique part number per profile and color. | A product code can be used for a group of products without separating color or profile, greatly reducing the number of product codes. |

| Ease of Sales Entry | No materials lists are used when selling panels. The same sales process is used to sell stock or custom panels. | Reduces the number of codes when selling panels. |

| Pricing | Pricing is based on standard pricing tools or the linear foot pricing. | Pricing can be based on either standard, linear foot, or materials list pricing of materials list lines. |

| Cost and Weight on Sales Orders | Cost and weight of panels are generated from the finished goods product records. | Cost and weight of panels are calculated based on the raw materials and other materials list records. |

| Recommendation | Use Track Count for stock panels. | Using No Count for custom panels is a simple process to use if no inventory value is needed between manufacturing and the sale. |

Trim

There are two methodologies for selling trim profiles: Track Count, which uses manufacturing to create trim stock based on color, profile, and size and No Count, which uses the materials list feature to reduce coil stock when trim is shipped and invoiced.

| Pros and Cons | Track Count | No Count |

| Finances | Tracks inventory value of stock trim as well as custom trim between the time product is manufactured and sold. Review manufacturing stock. | Raw materials COGS is processed when panels are sold. Manufactured panels are not inventoried at any time. Review Materials List Overview. |

| Inventory Control | Inventory is maintained for both stock and custom trim. | Metal coil is inventoried until trim is sold. Both standard and custom trim stock is not tracked. |

| Managing Part Numbers | Requires a unique part number per profile and color. | A product code can be used for a group of products without separating color or profile greatly reducing the number of product codes. The option is available to create separate product codes for sales history or create varied pricing. |

| Ease of Sales Entry | No materials lists are used when selling trim. The same sales process is used to sell stock or custom trim. | Reduces the number of codes when selling panels. |

| Custom profiles | Custom profiles must be set to No Count, calculating pricing based on width, length, and optional bends. | Using a materials list for custom profiles allows pricing to be dynamically set based on dimensions or bends. |

| Pricing | Pricing is based on the standard pricing tools or the linear foot pricing. | Pricing can be based on either standard, linear foot, or materials list pricing of materials list lines. |

| Cost and weight on sales order | Cost and weight of fixed length trim are generated from the finished goods product records. | Cost and weight of panels are calculated based on the raw materials and other materials list records. |

| Recommendation | Use Track Count for stock trim. | Using No Count for custom trim is a flexible process if no inventory value is needed between manufacturing and the sale. This method is very flexible if most trim is made-to-order rather than stocked. |

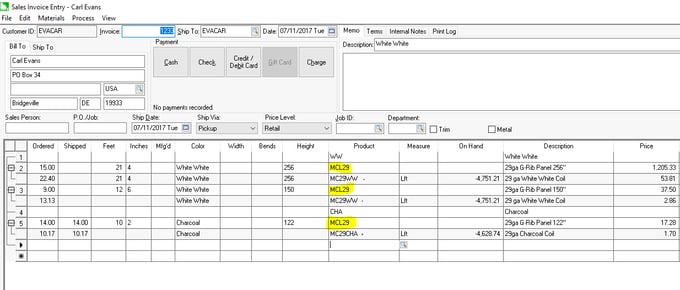

Color Management

The metal sales tools within EBMS gives the user the ability to add a color on a sales order and all trim entered below the color line will be set with the same color until another color line is entered. The color management tools only apply to product classified as No Count. (Review previous section of this article for inventory classification recommendations.)

Note the White color item (WW) sets the white product codes until the second color option: Charcoal is entered on the sales order.

Review the following color table:

| Metal Tab Usage | Item Type | Force Color Selection | Use Multi-Length | Color ID | Group Template |

| Color Codes | Color Code | FALSE | FALSE | Blank | Blank |

| Coil Place Holder | Coil Stock | TRUE | FALSE | Blank | Same as Product ID |

| Colored Coil Product | Coil Stock | FALSE | FALSE | Color Code Product ID | Coil Place Holder Product ID |

| Generic Formed Panel Product (No Count) | Formed Panel | TRUE | TRUE (Optional) | Blank | Blank |

| Generic Formed Panel Product (Track Count) | Formed Panel | TRUE | TRUE (Optional) | Blank | Generic Formed Panel ID |

| Setting up Standard Item to use color | Blank | TRUE | FALSE | Blank | Blank |

Review Setup Packages with Metal Components for instructions to configure multiple colors.

Color options are varied and may be complex. Contact a Koble Systems consultant for assistance in configuring color options to meet specific scenarios.

Metal Packages

Metal package needs are varied and may be complex. Contact a Koble Systems consultant for assistance in configuring metal kits to meet specific scenarios.

Kits containing multiple items are grouped into packages. Options such as color can be globally applied to the entire package. Review Metal Packages for details on this convenient sales tool.

Building Packages

Sell building packages efficiently using the EBMS software. Work orders, invoices, and packing lists are generated from one powerful order entry dialog, eliminating double entry. Product, labor, and services are packaged into flexible quote templates to sell using a single price. Work orders are generated from the quote and sent to the shop or roll former to streamline processes and keep your orders moving.

Review Proposals Templates for details on creating building package templates.

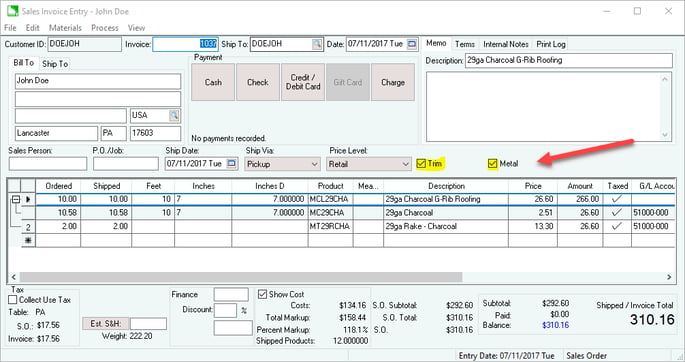

Pickup Email Confirmations

The optional EBMS metal tools include the ability to send email confirmations to the customer as soon as the order is completed. A sales order is considered completed when both Metal and Trim options are enabled on the Sales Invoice Entry page.

This feature requires the EBMS AutoSend feature to be installed and configured to send emails to a customer. Review Auto Send Sales Orders or Invoices for setup and feature details.

Review Metal Supply Shipping Dialog for more options to list orders combined for delivery.

Setup

Review Set Up Advanced Metal Tools for instructions to configure metal inventory products including components and color selection.